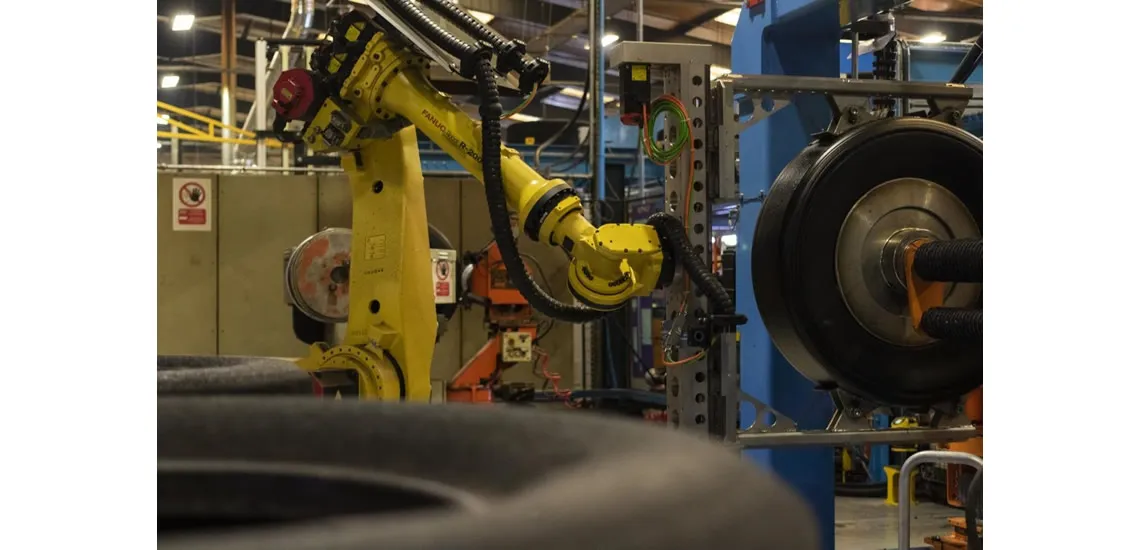

The recent installation of an ABC (Automated Build Cell) Robot is claimed to have produced a number of key benefits and efficiencies at Bandvulc’s Ivybridge plant in Devon in the UK.

Automated Build Cell Robot Installed

Head of Hot Retread Production at Bandvulc, Tony Mailling, explains more about how innovation and teamwork has progressed this exciting project: “Prior to the introduction of the ABC robot, the loading and unloading of the tyres onto the building machines was a completely manual process for our operatives. Now, the robot automatically loads the tyres onto the building machine from indexed conveyors, and the state-of-the-art extrusion technology applies the new compound onto the tread and sidewall of the prepared casing before it is cured in the press.

“The installation has already delivered an efficiency gain by freeing up operational staff for a more technical monitoring role or to develop their skills in other areas of the plant. Our investment in automation is about improving the working environment for all our employees and making it safer.

“As we continue to develop the automation of the plant, it not only makes it more efficient, but it also improves daily life for our people and that’s of fundamental importance,” he added.

Bandvulc has a team of experts in rubber technology, research, and development and importantly for this project, engineering. The design and installation of the ABC robot has been carried out in house by Bandvulc’s own engineering team.

“None of our leading developments in retreading technology would be possible without our people,” said Mailling. “It’s been a great opportunity for all areas of our workforce to collaborate on such a big project, from the engineers who installed the robot, to the technical team who ensured the new automation was seamlessly integrated into the plant database. Apprentices have also been heavily involved in the installation, encouraging them to learn new skills and achieve a greater understanding of how the industry and technology is progressing.”

The ABC project is part of Bandvulc’s three-year development plan to ensure the manufacturing plant continues to develop innovative retreading technologies and drives further efficiencies both for its plant and its people.