Continental has taken a focused view of the construction industry , and at Bauma 2023, the company focused on the benefits of digital technology

Continental’s Offers a Considered View on Construction Tyres

Continental’s view gave a very open response to the questions put to it by Commercial Tyre Business.

On the question of the move from bias to radial tyres, Continental clarified that, in general, it is essential to use the correct tyre technology for the right application and task. Reinhard Klant, Product Manager for Earthmover Tyres, explained; “We are noticing a trend towards radial tyres. But depending on the type of task the vehicles are to perform; a decision must be made as to which tyre design is suitable.

Radial tyres are mainly used for long-distance (load and carry) applications, whereas bias tyres make sense for short distances, low speeds, and tilting stability, e.g., telehandler applications. For applications like backhoe and motor grader, more radial tyre options are indeed coming on the market all the time that traditionally would have been bias.

“For some applications, solid tyres can also be a suitable option as well as rubber tracks.”

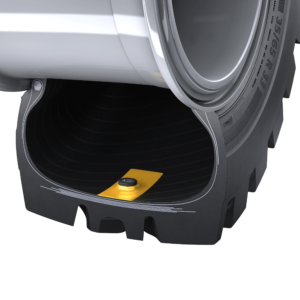

Continental is at the forefront of digital technology in tyre management, including areas such as TPMS, digital connectivity, using AI to monitor tyre condition, etc. In the construction sector, tyre management issues are magnified by the size of the vehicles and their tyres (or tracks). At Bauma, Continental illustrated some of the advantages that digitisation could bring to the sector.

Digital Tyres from Continental

Matthew Futrelle, Head of Business Field Earthmover Tyres, explained; “Digitalisation is one of the big megatrends in the construction and earthmover industry. Today, data and digital tyre management are strategic solutions to delivering full transparency, productivity, and the lowest total cost of ownership. We at Continental deliver all our radial earthmover tyres onto the market with sensors inside. Integrated tyre sensors and tyre management systems like ContiConnect support in reducing fuel consumption and therefore cut emissions; they assist in reducing downtimes, assuring safety, increasing the overall lifetime of the tyre, and saving costs in the long run.”

Of course, the sensors are just part of the system, and TPMS has been around for a long time in various guises. However, Continental is taking digitalisation in the construction sector to the next level.

“The sensor inside our radial tyres makes our tyres ready for use with ContiConnect, our digital tyre management system,” adds Futrelle. “The sensors transmit data in real-time about the inflation pressure and temperature. Warnings can be shown to the operator on an in-cabin display or vehicle dashboard, or to the fleet manager on web-based ContiConnect when tyres are underinflated or at risk of overheating. If the tyre pressure is optimised, the operator can save up to 15 minutes per vehicle (195 hours a year) for inspection, increase fuel efficiency by 1% and gain 15% longer tread life on average – versus a tyre that is 10% underinflated.

“Additionally, the next-gen Bluetooth sensor offers fleet customers the option to track their tyres as an asset and to monitor tyres via mobile devices in a much simpler and more convenient way, for example, with a smartphone (thanks to Bluetooth-capability). In addition to inflation pressure and temperature, performance parameters from fleet checks, such as tread depth and tyre condition, can be tracked. With ContiConnect, the fleet manager maintains complete fleet control at any time in any place.

We are noticing that digital solutions are much appreciated in the industry but need to be user-friendly. Therefore, we are now offering the lite version of ContiConnect. This is a free-of-charge version with app-based functionalities. The “lite” version enables the tyre pressure and temperature to be checked easily; no additional hardware or vehicle modifications are required. The prerequisite is that the tyre is already equipped with the sensor. This provides easy access to the world of digital tyre management and is a starting point for those interested in experiencing the advantages of digital tyre monitoring.”

Futrelle concluded; “Digitalisation is one of the big megatrends in the construction and mining industries. We are noticing that digital solutions are much appreciated, but there is also a need to be user-friendly. Therefore, we are now offering our lite version of ContiConnect. Now you can easily connect to your tyre assets from the palm of your hand.”

Klant agreed; “The sensor inside our radial tyres makes our tyres ready for use with ContiConnect. The digital tyre management system supports reducing fuel consumption and, therefore, cut emissions; they assist in avoiding downtimes, assuring safety, increasing the overall lifetime of the tyre, and saving costs.”

A range dedicated to the construction sector

Construction and earthmover tyres face some rigorous applications, and working on building sites, quarries and other harsh conditions, there is always a risk of higher levels of damage to a tyre than on conventional road use.

Continental’s earthmover tyre range is specifically designed for applications in very harsh conditions and is made to meet the highest level of performance, safety, and durability. Parameters like compound technology, pattern design and digital solutions support the longevity of Continental’s tyres. e.g., our cut-resistant compound.

The polymer meshing system makes the tyre resistant to cuts, chips and chunks and reduces overall tyre abrasion, e.g., in our RDT-Master product line. Due to the specifically designed 3D network, the compound enables the surface to flex over rough terrain and sharp objects without damaging or tearing the network. At the same time, it also ensures low abrasion for good mileage.

“Our Earthmover tyre range is specifically designed for applications in very harsh conditions and made to meet the highest level of performance, safety, and durability.” Says Futrelle. “We focus on areas like compound technologies, pattern design and digital solutions to support the longevity of our tyres – for example, our cut-resistant compound.”

Continental has solutions designed to assist in fleet tyre management in construction operations. However, the challenge constantly changes as there is a dive to ever bigger and heavier machinery in the construction sector. Which, in turn, drives ever-improved tyre performance requirements.

The lifecycle of construction machinery and their tyres in the earthmoving and construction industry is crucial due to the harsh environment in which they operate. We see that new machines are becoming more and more efficient.

Kant outlines the Continental approach; “Heavy loads, higher horsepower, high temperatures, abrasive surfaces, and a lack of time are putting the vehicle tyres under pressure. New, heavier machines aim to move more material and to complete more load cycles in a shorter time. To meet these conditions, we strongly focus on customer and market needs as well as on new product developments and digital solutions to increase efficiency and sustainability. To minimise idle time, reduce fuel consumption and ensure serviceability even under those harsh conditions, the tyres should be controlled as precisely as possible. To ensure this, we rely on digital tyre management systems and offer enhanced consultancy in fleet management, e.g., by optimising driving routes via the ContiLogger Live system.”

This, then, is all about control and reducing unnecessary journeys and the fleet operator having a real-time involvement in the operations of vehicles on a site.

Klant adds; “The lifecycle of construction machinery and their tyres in the earthmoving and construction industry is crucial due to the harsh environment they operate in. The tyres should be controlled as precisely as possible to meet these conditions. To ensure this, we rely on digital tyre management systems and offer enhanced consultancy in fleet management, for example, by optimising driving routes via the ContiLogger Live system.”

Earthmoving Tyres need to perform consistently and reach their maximum life span. Therefore, Continental has developed two comprehensive and resistant tyre portfolios: The ContiEarth and ContiMine. There are four product lines (EM-Master E3/L3; EM-Master E4/L4; RDT-Master, LD-Master, Telemaster) for construction and surface applications and two product lines dedicated to the underground mining business (DrillMaster; DumperMaster). The features of each product line are developed and optimised to fit the machine type and application perfectly.

Futrelle continues; “Our digital solutions like ContiConnect and enhanced consultancy are essential to our offerings, enabling us to optimise efficiency for our end users. That’s why all Continental Radial Earthmover Tyres come onto the market with sensors installed from our factories.”

Continental Retreading and Sustainability

Continental has made retreading an essential element of its offer to the truck tyre sector. With the volumes of rubber involved and the cost of casings in the earthmover sector, retreading must play a role here as much as it does in the truck sector.

Kant answers; “We believe that circular economy is a key element in the construction tyre sector. The materials used to build a performing earthmoving OTR tyre can easily exceed the weight of one tonne and far beyond. The tyre carcass can be reused during the retreading process – giving the tyre carcass a new tyre life by adding and processing part of the tread material. Consequently, a higher number of successful tyre retreads is a huge step ahead in sustainability contribution.

“Tyre management systems like ContiConnect are also playing a decisive role here. Constant inflation pressure control and maintenance ensure that the valuable tyre carcass of premium tyres is better protected. This is increasing, by a double-digit percentage, the chance for tyre retreadability and thus increasing the option for the resource-saving, sustainable retreading of tyres.”

Retreading is an essential and tangible element of sustainability, and Continental is increasingly aware of the need to be sustainable in its products and operations. The careful use of limited world resources is essential for successful and growing sustainability in society. The tyre industry, specifically the construction and mining tyre industry, continues to move towards more efficient, more sustainable vehicles, products, and processes with more sustainable materials. Futrelle outlines Continental’s aims in the construction sector; “Our goal is to be the most progressive tyre company in terms of environmental and social responsibility. We aim that by 2050, at the latest, all our tyres will be made of sustainable materials. Relentlessly, we drive forward innovative technologies and sustainable solutions along our entire value chain. Today, our products, like our intelligent tyres, are essential to prevent punctures and downtime and increase sustainability through efficiency. Our tyre monitoring system, like ContiConnect, supports that the tyres run under optimum conditions. This promotes longevity, reduces fuel consumption, and minimises idle time. And will consequently reduce the CO2 footprint during operation. The tyre industry, specifically the construction and mining tyre industry, continues to move towards more efficient, more sustainable vehicles, products, and processes with more sustainable materials. Our goal is to be the most progressive tyre company in terms of environmental and social responsibility.”